Galvanizli Çelik Bağlantılı Oval Boru Rulo Formasyon Makinesi

Elektrik boruları ve kablolama boruları için uzmanlaşmış

BizimBirbiriyle bağlantılı oval boru rulo şekillendirme makinesiElektrik boruları veya kablolama boruları için seri üretimde ince duvarlı oval borularda hassasiyet ve verimlilik için tasarlanmıştır.birbirine bağlı oval borular yaratır ( ince malzemeler için kaynak gerekmez) ve kolay boru bağlantısı için boyun gibi kilit işlevleri entegre eder, dikişsiz boru yapıları.

Temel Uygulama: Elektrik Hattı ve Kablolama Kanalları için Oval Borular

Bu makine tarafından üretilen birbirine bağlı oval borular elektrik sistemlerinde iki kritik rolü yerine getirir:

- Elektrik boruları:Elektrikli kabloları dış hasarlardan (örneğin darbe, nem) uzun süreli güvenliği sağlayan kapalı, birbirine bağlı bir yapıyla koruyun.

- Elektrikli kablolama boruları:Endüstriyel veya ticari ortamlarda kablolamaları düzenleyin ve yönlendirin, yer tasarrufu kurulum ve kolay erişim için oval şekli kullanın.

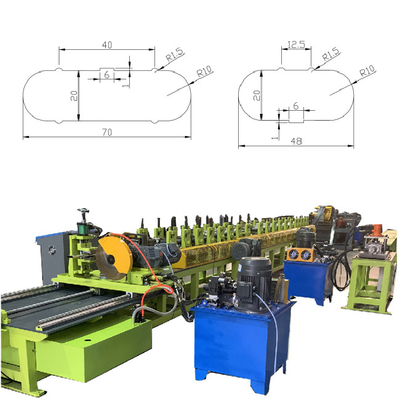

Referansınız için oval boruların ayrıntılı çizim profillerini hazırladık. Boyutların elektrik projenizle uyumlu olup olmadığını kontrol etmek için bizimle iletişime geçin.

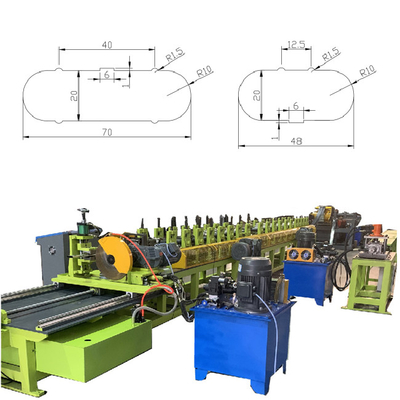

Tam Makine Yapılandırması: Decoiling'den bitmiş boruya kadar

Birbirine bağlı oval boru rulo şekillendirme makinesi, uçtan uca oval boru üretimi için gerekli tüm bileşenleri entegre eder:

- 3 tonluk el yapımı kabuk çıkartıcı:Çiğ malzeme bobinlerini (galvanizli veya önceden boyanmış çelik) istikrarlı bir şekilde açar, böylece istikrarlı bir malzeme arzı sağlar.

- Besleme birimi:Hızını ve hammadde beslemesinin hizalanmasını kontrol eder, kolay ayarlamalar için manuel çalışma desteği ile.

- Soğutma sistemi:Rollerin ve malzemelerin şekillendirilme sırasında aşırı ısınmasını önler, makine bileşenlerini korur.

- Rulo şekillendirme sistemi:Makinenin kalbi, yassı metal levhaları birbirine bağlanmış bir dikişli hassas rulolar aracılığıyla oval profillere şekillendirir.

- Işınlama sistemi:Rulo şekillendirme ve besleme ünitelerini eşzamanlı olarak sürüyor, tekdüze şekillendirme hızını koruyor.

- Kesme sistemi:İstediğiniz uzunluğa oval boruları tamamlayarak, tutarlı boyutları sağlar.

- Kontrol sistemi:Tüm bileşenlerin çalışmasını merkezileştirir, parametrelerin ayarlanmasını basitleştirir.

- Çıkış Destek Taşıyıcısı:Bitmiş boruların makinenin dışına çıkışlarını destekler, bükülmesini veya hasar görmesini önler.

Uyumlu malzemeler ve kalınlık sınırları

| Özellik |

Spesifikasyon |

| Uygun Malzemeler |

Galvanizli çelik veya önceden boyanmış çelik (korrozyona dayanıklı) |

| Bağlantılı olarak uygulanabilir kalınlık |

0.3-1.2mm (daldırma gerekmez) |

| 1.2 mm'den fazla kalınlık |

Saldırma sistemi veya ikincil şekillendirme makinesi ile eşleştirme gerektirir |

Anahtar özelleştirme: Çok Boyutlu Borular için Hızlı Değişim Tasarımı

BizimHızlı değişim tasarımıEkonomik bir çok boyutlu üretime izin verir:

- Roller ve oçaklar kolay boyut değişimi için özel bir taban çerçevesine monte edilir

- Çifte paylaşılan bileşenlere yatırımı azaltır

- Hem ekonomik hem de yüksek kaliteli konfigürasyonlarda mevcuttur

Kolay Tüp Bağlantısı: Güvenli Aşırma için Boynuzlama Makinesi

Entegreboynuzlama makinesidikişsiz boru bağlantıları sağlar:

- Bir boru ucunun çapını azaltır (güçlendirici kaburgalarla) yerleştirmek için

- Ek bağlayıcılar olmadan sıkı, güvenli bağlantılar yaratır

- Montajı basitleştirir ve yapısal istikrarı artırır

Tüm Sürece Bakın: Çalışma Videolarını İsteyin

Decoiling'den bitmiş boruya kadar tüm üretim döngüsünü gösteren ayrıntılı bir çalışma videosuna erişmek için bizimle iletişime geçin.

İhtiyaçlarınıza Uyum Sağlayın

Makineyi boru boyutları, malzeme kalınlığı veya üretim ihtiyaçları için özel gereksinimlerinize göre ayarlayabiliriz.veya özelleştirme seçenekleri.

Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!  Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!